Virtual Factory TourSteel ball manufacturing process

Please scroll sideways.

1.Material

First, there is a raw material. We choose the best iron as the original material, and have the iron rod specially manufactured for our company with the specific components at the steel mill.

- When the iron wire is manufactured at the steel mill, the iron is burned red hot and stretched to make the iron wire. At that time, the scale (oxide film) is attached to the surface.

2.Drawing

We draw the iron wire rod to the exact size to make it easier to press

(about 1 ton).

- You can not press the iron wire as it is from the steel mill. You need to get rid of the scale (acid cleaning), coat with lubricant, make a uniform metal component, draw and stretch to a precise diameter and then roll it up to the carrier. Once in a while when a thick wire is drawn and stretched into a thin wire, it hardens and becomes unusable. In this case, we use heat treatment (annealing).

- I didn't know that. How long would a ton of wire be?

- Well, the length may vary depending on the diameter of the iron wire. The picture shows the iron wire material for the Pachinko balls, and the length of the iron wire is about 3KM (1.8mile). The diameter of the Pachinko ball is determined to be 11mm. For other steel balls, the diameter of the iron wire material needs to be about 2/3 of the diameter of the final ball product.

- I see.

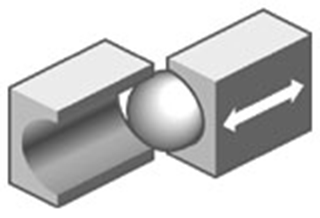

3.Heading

Using the stretched iron wire as the raw material, we cut the wire to pieces of certain size with the ball header, we then press it with the metal mold to create the ball shaped blank (pressed blank balls).

- Wow! This is amazing! It makes balls by crushing from both sides. It's like machine guns.

- Yes. Since the iron is force-pressed by the metal mold, it generates tremendous heat so you can't pick it up with your bare hands.

- Well, I see. This is terrific...

4.Flashing

In this step, we remove the flash from the pressed blank balls using the flashing machine.

- Wow! it's so loud! It sounds like a thunderbolt!

- The flash of the blank ball is removed by rolling it in between the two revolving striated metal plates.

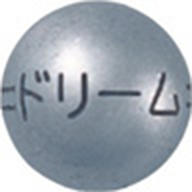

5.Punch marking (special process for Pachinko balls)

The special puncheon uses the metal mold with a mark specified by a customer. Then the balls are rolled in between the metal mold and the mark is punched.

- Can you punch graphics too?

- Sure! In many cases, marks are logos of our customers. Although it depends on the size of the letter, we can punch marks with up to 10 letters.

- I see!, so you can print my name on the Pachinko balls?

- Yes, indeed!

6.Heat treatment (carburizing and quenching)

Carburizing --> Quenching

- It is really hot here!!

- Yes. We do heat treatment here. This is where we harden the steel balls by burning them at a very high temperature.

- Hardening iron with heat?

-

Yes! First off, we put the flashed steel balls into the revolving retort oven together with coal briquettes, close the oven and heat it up until the temperature inside gets to 900 degrees. This carburizes the ball and the carbon ratio is increased to a depth of 1mm from the surface of the steel ball.

Carburizing --> Quenching --> Tempering

Note: Carburizing and quenching are the heat treatment processes for the low carbon steel balls. - Thanks, I learned a lot.

7.Surface compression

Removing scale after the heat treatment.

- After the heat treatment, we remove the scale of the steel balls by hitting them with other balls. In addition, this compresses the surface component and hardens the surface a little bit more and increases the durability of the balls. We call this shot peening process.

8.Grinding and Lapping

Since the ball may have become distorted a bit by the mark punching and heat treatment, we now shape the steel balls (Pachinko balls) to the precise size with the lapping machine.

-

Grinding and lapping finishes the steel balls by using a striated metal plate and grinding stone. The grinding stone is changed from a rough one to a fine one with at least three processes for the steel balls.

In case the balls requires super precision, we do the wrapping process which uses two striated metal plates and liquid with super fine polishing materials in it, and polish it to a mirror finish.

9.Polish (special process for Pachinko balls)

We polish the surface of the lapped steel balls to a mirror finish.

For low grade steel balls and Pachinko balls, they are polished to a mirror finish after the grinding and lapping. This is a necessary process for the beautiful plating (coating).

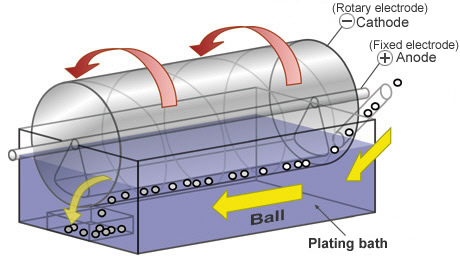

10.Plating (special process for Pachinko balls)

In order to increase the gloss and the rust/abrasion proof coefficient, we do the hard chrome plating. Our plating equipment was designed specially for the Pachinko balls making it possible to plate the surface of all of the balls equally.

- What is the special plating equipment?

-

Please listen carefully as it's a bit complex!

The hard chrome plating requires a lot of electricity. Usually, plating is done by holding the area where the plating is not required, but this method does not work for balls which require plating on the entire surface. - Oh, that's not good for the balls, I see.

- So we need to plate the ball by rolling it in between the electrodes. The distance between two electrodes needs to be small in order to run a lot of electricity. However, if both electrodes touch each other, it will cause a spark and the plating would not be performed correctly, so we need to be careful in this process.

- OK, I understand that it's a difficult thing. I am amazed to know that it takes so much work and process to make one tiny Pachinko ball.

11.Tinting (special process for Pachinko balls)

Tinting is done by running the color paint into the mark on the surface of the Pachinko ball. It makes the mark of the balls stand out.

12.Inspection and Packaging

All the steel balls and Pachinko balls are visually inspected by an experienced worker and are also inspected by the automatic inspection equipment before packaging to make sure that only the finest quality balls are packaged and shipped to our customers.