Technical documents

-

Standard accuracy of our products

Sato Tekko offers only the highest quality ball products.

-

Steel Ball Size Chart

Steel ball sizes based on inches are summarized in the table with inch and millimeter sizes.

-

JIS standard for steel balls

To ensure that there is no variation in the processed ball, a method of measurement and representation is defined for the ball.

-

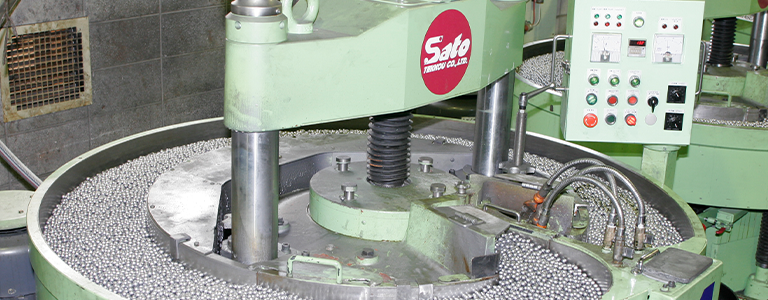

Virtual Factory Tour

Dr. Sphere tells us about the manufacturing process of how steel balls are made.